5 Gallon Preform Blowing Machine Pet Blower Machine

Ürün Detayları

Model | MS-20L |

Theoretical Capacity | 60-240BPH |

Mold Cavities | 1 |

Neck Size | 55mm |

Max. Volume | 20 Liter / 5 gallon |

Advantages | Suitable for various PET bottles from 100ml to 20L, wide range of application. Infrared heaters, independently adjustable, simple structure, stable running. |

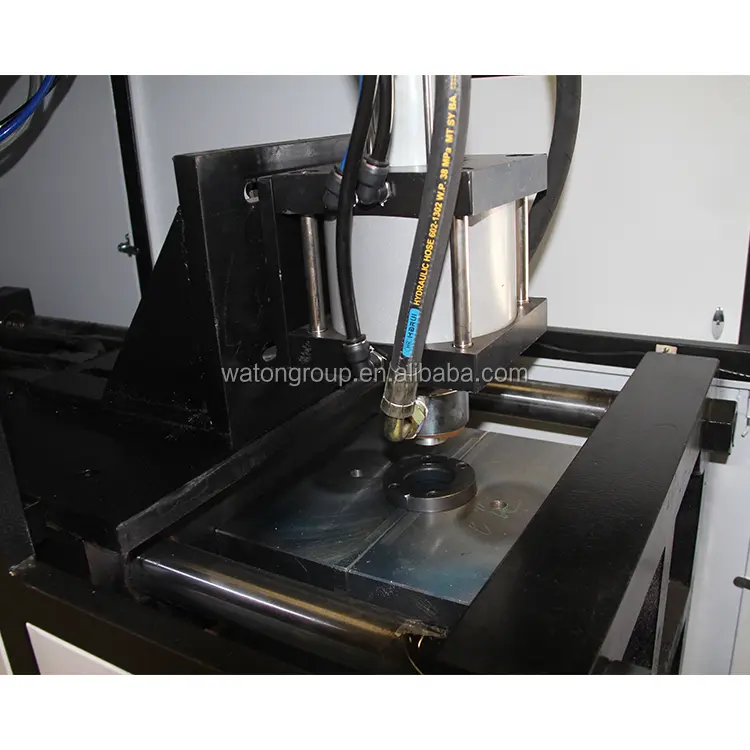

MS Series is traditional model of Semi-automatic Stretch-Blow Molding Machine. Each set of MS Series Semi-Automatic Blow Molding Machine is composed by two parts: Bottle Blower and Infrared Preform Oven.Suitable for various PET bottles from 100ml to 20L, wide range of application. Infrared heaters, independently adjustable, simple structure, stable running.

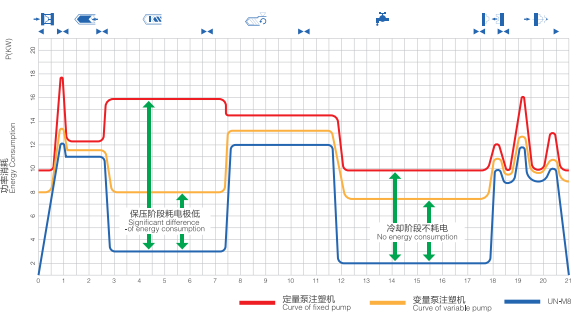

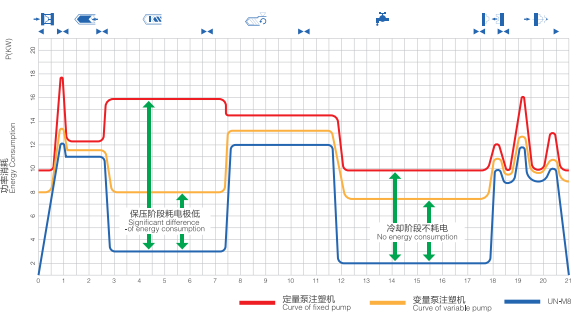

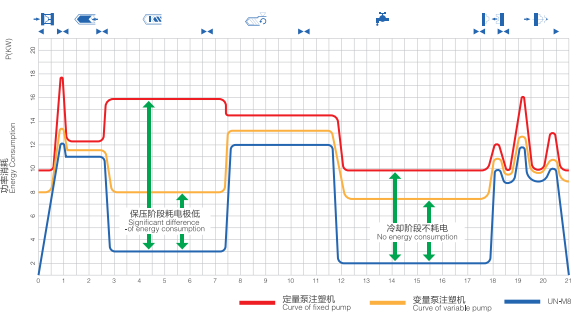

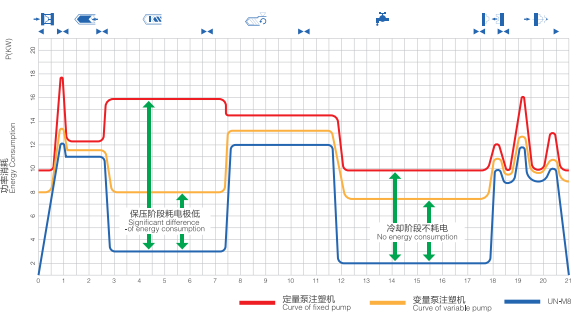

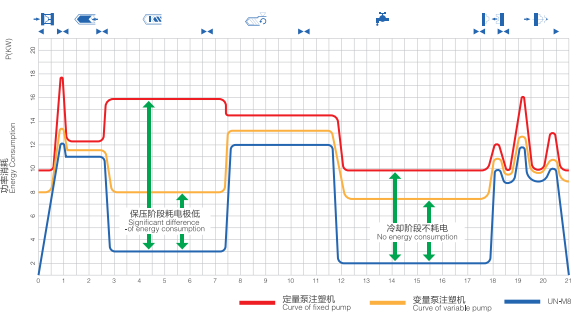

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.