Automatic Beverage Bottle Blow Molding Machine

Models | ECO-4L |

Theoretical Capacity | 3600-4500 BPH |

Mold Cavities | 4 |

Neck Size | 18-38 mm |

Max. Volume | 2000 ml |

Advantages | High productivity; easy to operate; long time after-sale service. |

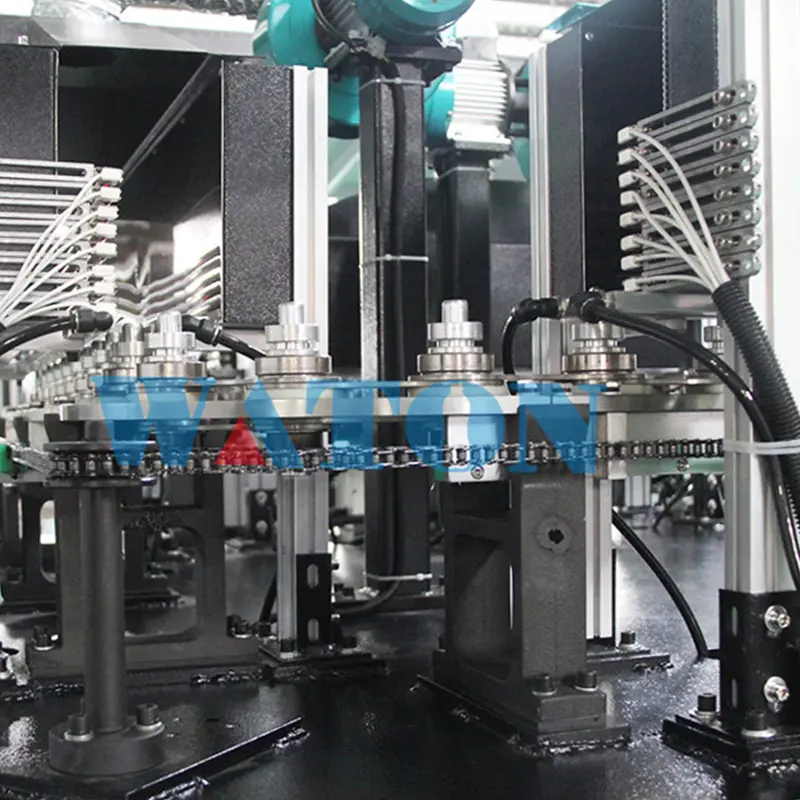

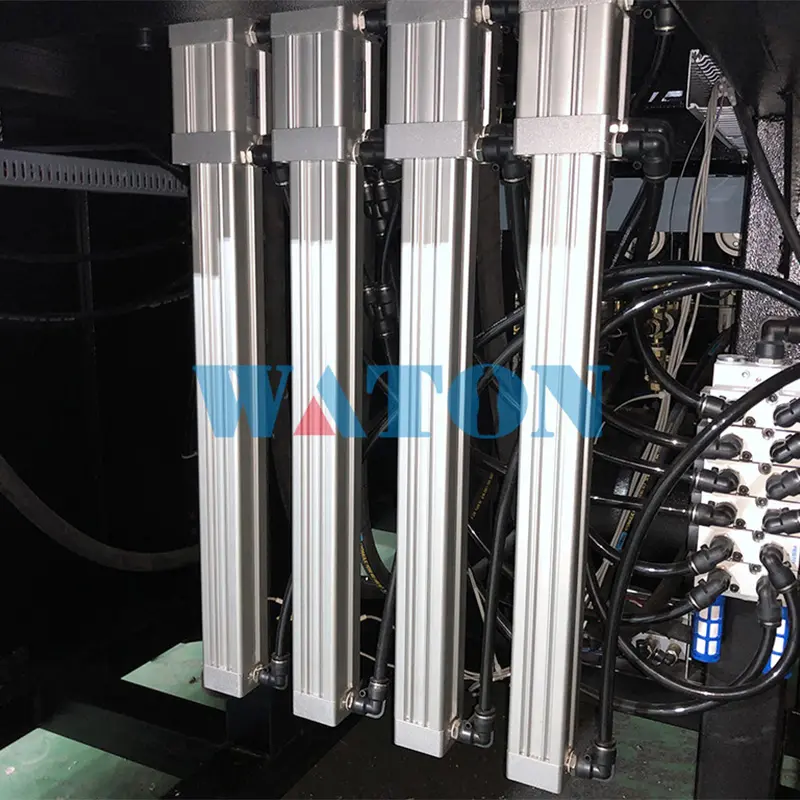

2. Driven by high-quality air cylinder, no pollution and low noise.

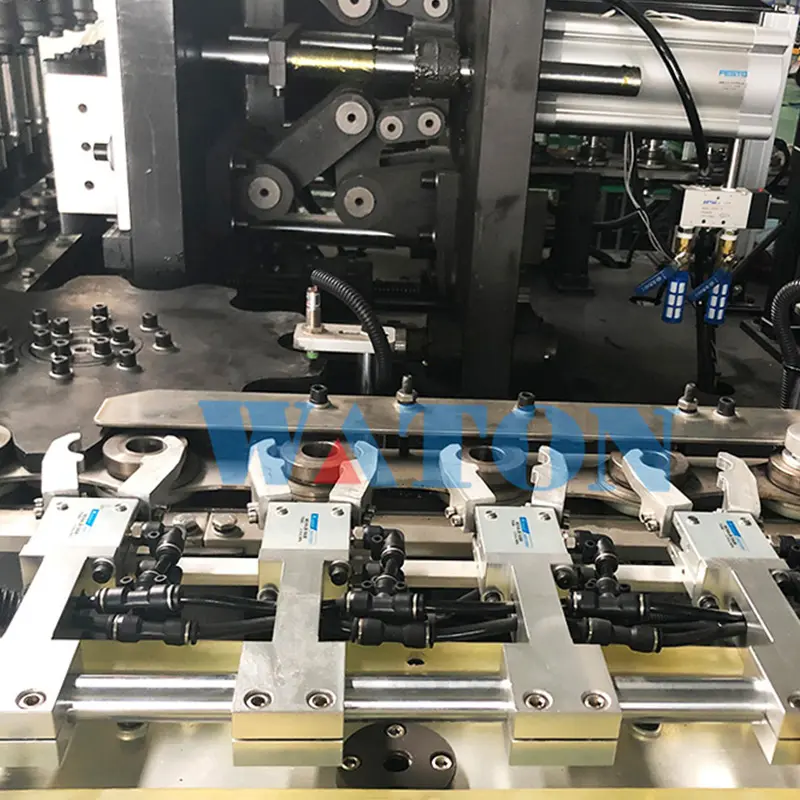

3. Equipped with preform loading machine and robot arm to ensure preform deliverying, sorting, loading and bottle take-out are performed in a fully automatic way, saving time and energy.

4. Controlled by good quality HMI with PLC, simple operation and accurate response.

5. Designed with automatic alarm device and automatic fault detection device.

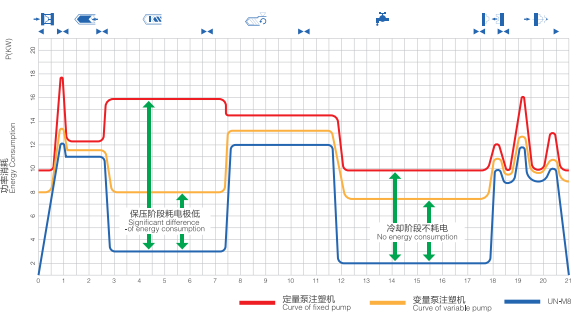

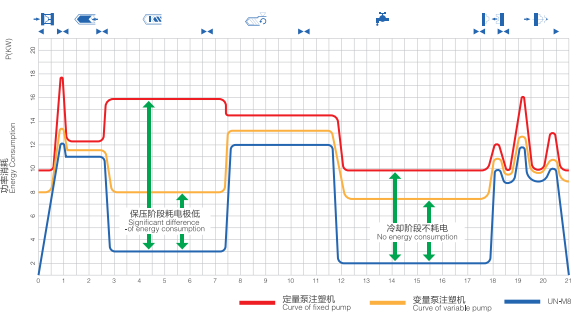

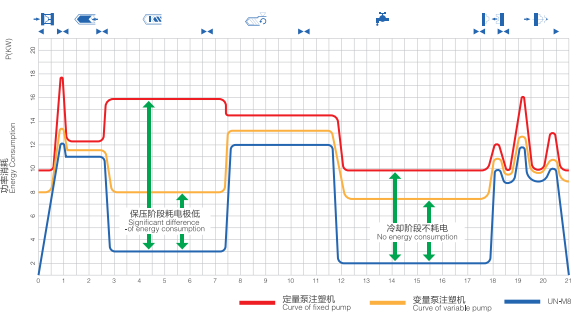

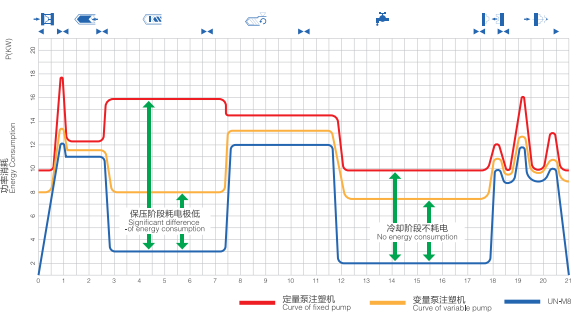

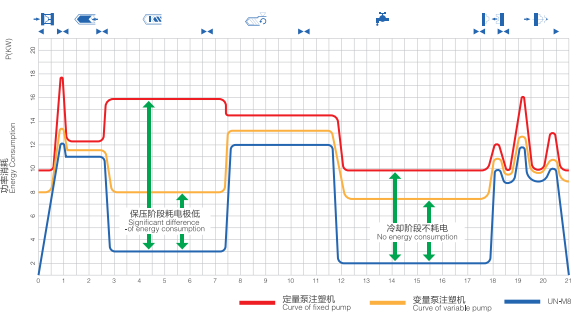

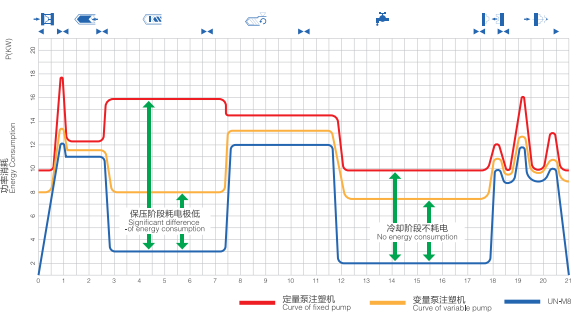

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.