ECO-2 Hot 2020 1 Liter Blow Molding Machine

Ürün Detayları

Models | ECO-2L |

Theoretical Capacity | 1800-2400 BPH |

Mold Cavities | 2 |

Neck Size | 18-38 mm |

Max. Volume | 2000 ml |

Advantages | High productivity; easy to operate; long time after-sale service. |

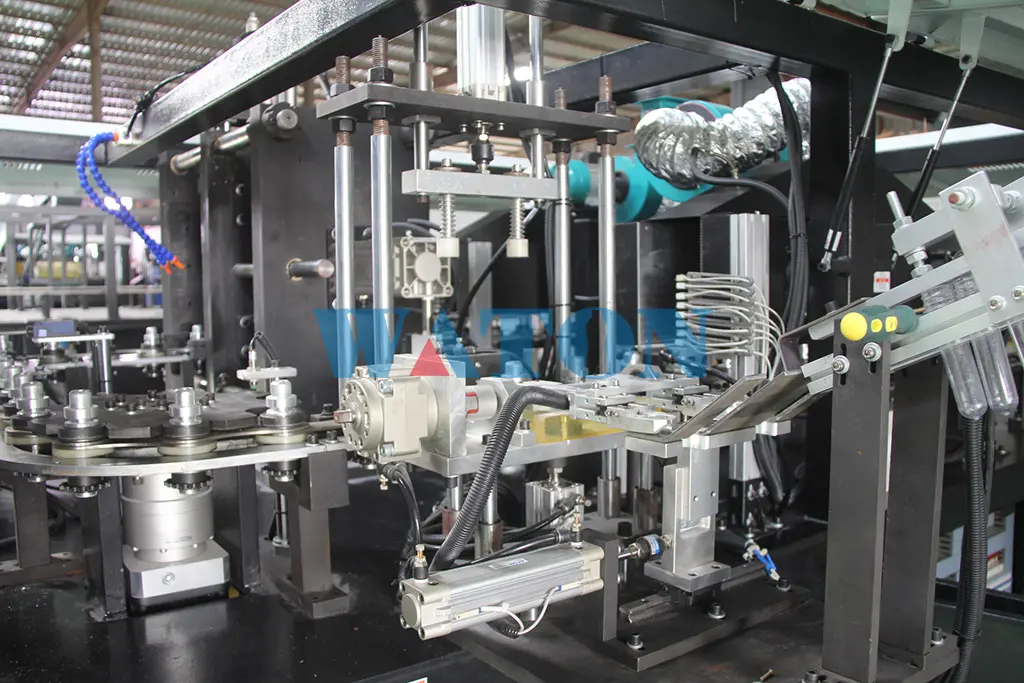

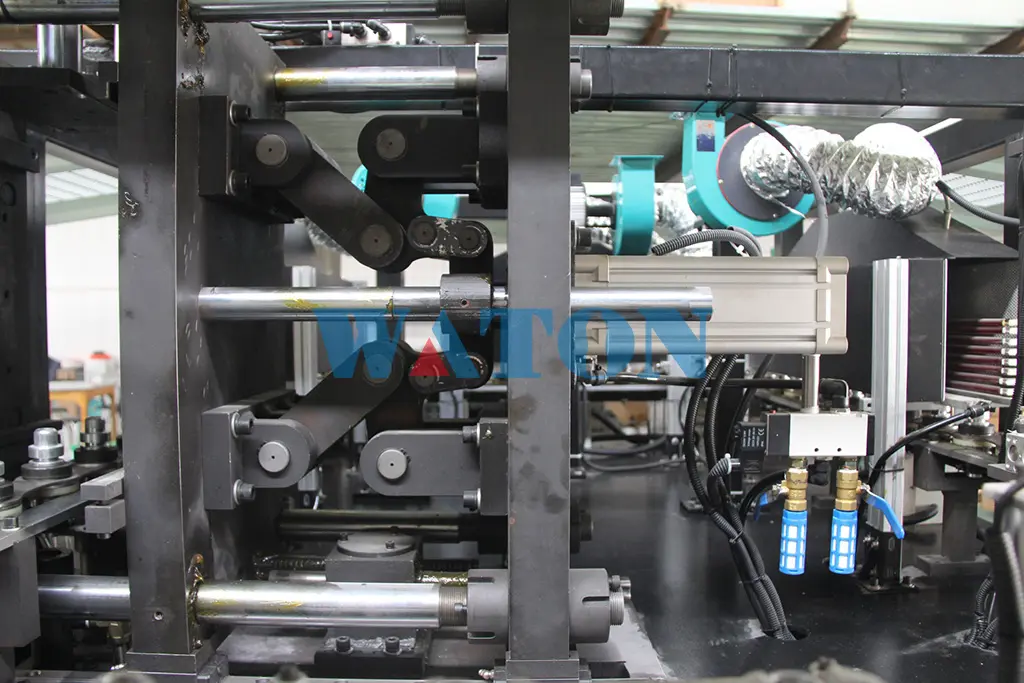

Model ECO-2L Automatic Bottle Blowing Machine is newly designed and reformed on previous experience of our manufacture. Main feature of this model:

1.Servo motor controls the preform stepping motion;

2.Compact with 2 cavities, center distance 139.7mm;

3.Newly high efficiency Ruby Heaters;

4.It is an ideal equipment to make different-shaped containers, such as mineral water bottle, beverage bottle, cosmetics bottle, medicine bottle, pesticide bottle, edible-oil bottle, wine bottle, milk bottle, etc. With reasonable investment and high efficiency, it helps you raise production and save energy.

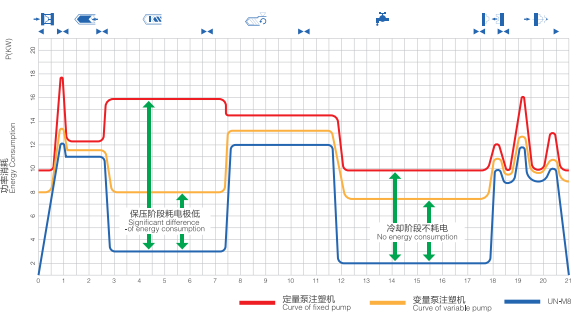

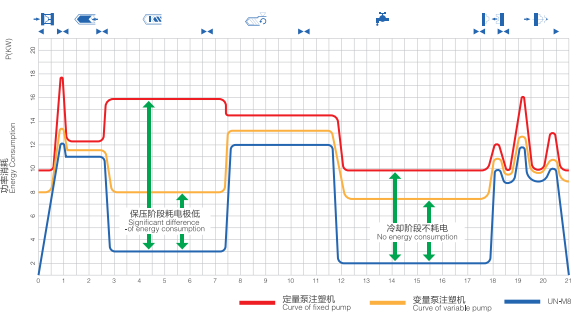

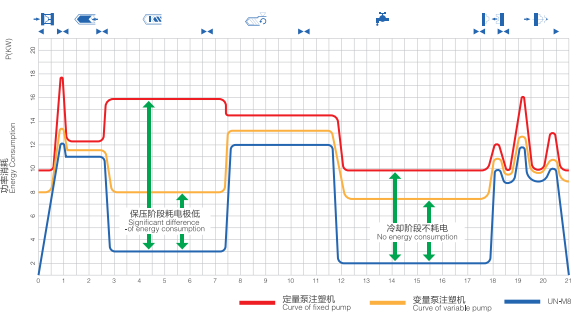

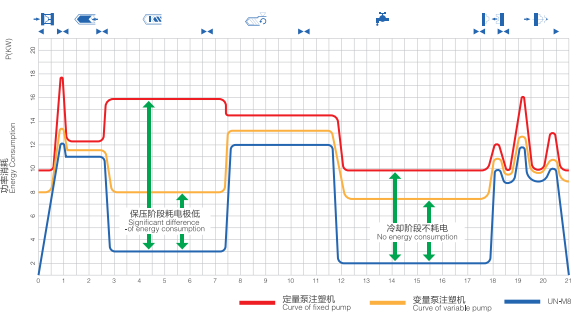

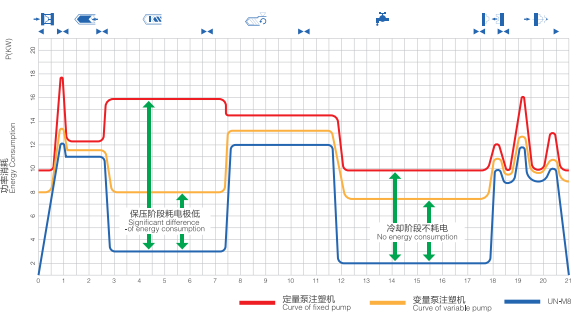

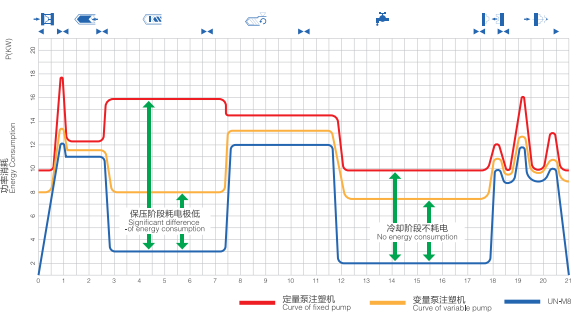

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.

Equipped With High Performance Servo System. The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy. During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low. The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Improves Injection Accuracy While Saving Power, Water And Reducing Noise. A Real New Revolution In Hydraulic Injection Molding Machines.