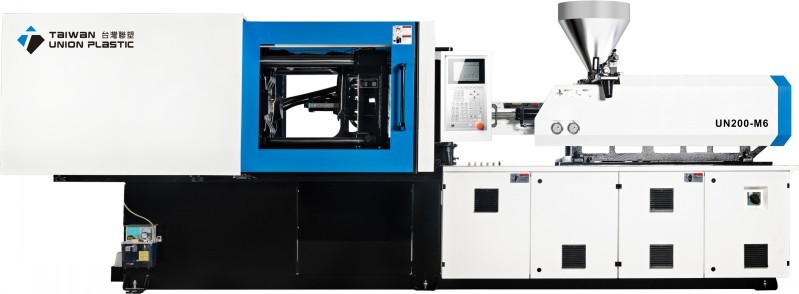

UN SERIES M6 PLASTIC MOLDING INJECTION MACHINE

– UN-M6 Is Equipped With High Performance Servo System The Output Power Of The Servo Motor Changes With Load, Without Loss Of Excess Energy.

– During Pressure Holding, The Motor Reduces The Speed And Theenergy Consumption Is Extremely Low The Motor Does Not Workduring Cooling And The Energy Consumption Is Zero. Lmproves Injection Accuracy While Saving Power, Water And Reducingnoise A Real New Revolution In Hydraulic Injection Molding Machines

– Equipped With Special Controller For ,Injection Molding Machine, Adopts Full Digital Control And Multiple CPU Divis,On Processing To Improve The Control System Execution Speed And Machine Working Accuracy And

Monitor The Production Process In Real Time, Showing Various Fault Diagnosis Able To Eqiup With MES System To Realize Network Management Of Product On Work Shop.

– The Injection And Plasticizing System Adopts Linear Guide With High Precision, High Rigidity And Low Friction, Provides Lowresistance And Stable Movement During Injection And Plasticizing. Adjustable And Sensitive, Better For Materials In Low Viscosity And Requires High Temperature.

– Small Size, High Cooling Efficiency, Simple Oil Circuit, Ensuring Stable Oil Temperature.

– Optimized Platen Design,One-Piece Casting Of Toggle Seat And Moving Platenone-Piece Casting Of Crosshead Guide Supporttoggle Seat And Rear Platen. It Not Only Improves The Rigidity But Also The Accuracy Of Mold Opening.

– Speed Increased By More Than 25%

– Even Lubricating Oil Distribution, High Lubricating Efficiency, And Extends Toggle Life.

– Sliding Foot Adopts Special Wear-Resistant Materialable To Adjust The Height And Balance The Weightdurable And Clean